Has it ever occurred to you that heaters usually tend to stop when you need them the most? Or have you heard of having hot spots on your car seats? Well, earlier we all were dependent on fixing such issues using fixed-resistance heaters. However, safety remains one of the most crucial underlying factors when only a single sensor provides you with the temperature of the heater. Despite the issues that have set back the usage of traditional heaters, Narain Cooling has an answer to overcome all such issues, using a PTC heater.

Let’s first understand what is PTC heater and how they work.

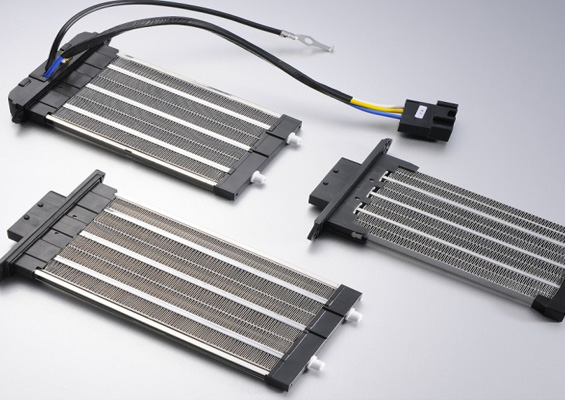

What is PTC Heater?

Positive Temperature Coefficients are self-regulating heaters. It consists of specialized heating discs made up of advanced ceramic materials. They run open-loop without the need for any external diagnostic controls. Unlike the traditional heaters that require wires and coils to produce heat, PTC heaters themselves use conductive inks. These inks are printed on flexible and thin polymer substrates.

These heaters are ideal for products that require faster, safer, and uniform heating. The characteristics of this heating system provide high efficiency and reliability as they allow it to act as its sensor, thus eliminating the need for external control. As a result, the heater lowers the risk of overheating.

PTC heaters use temperature coefficient materials that exhibit positive resistance to changes in the temperature.

Given the traits of PTC heaters, these are widely used for different purposes in industries & applications. They have been used in the automotive industry for decades now, where it thrives to survive in extreme conditions and environments. The robustness of PTC heaters has proved from car seats to surgical tubes and a wide range of applications in different industries.

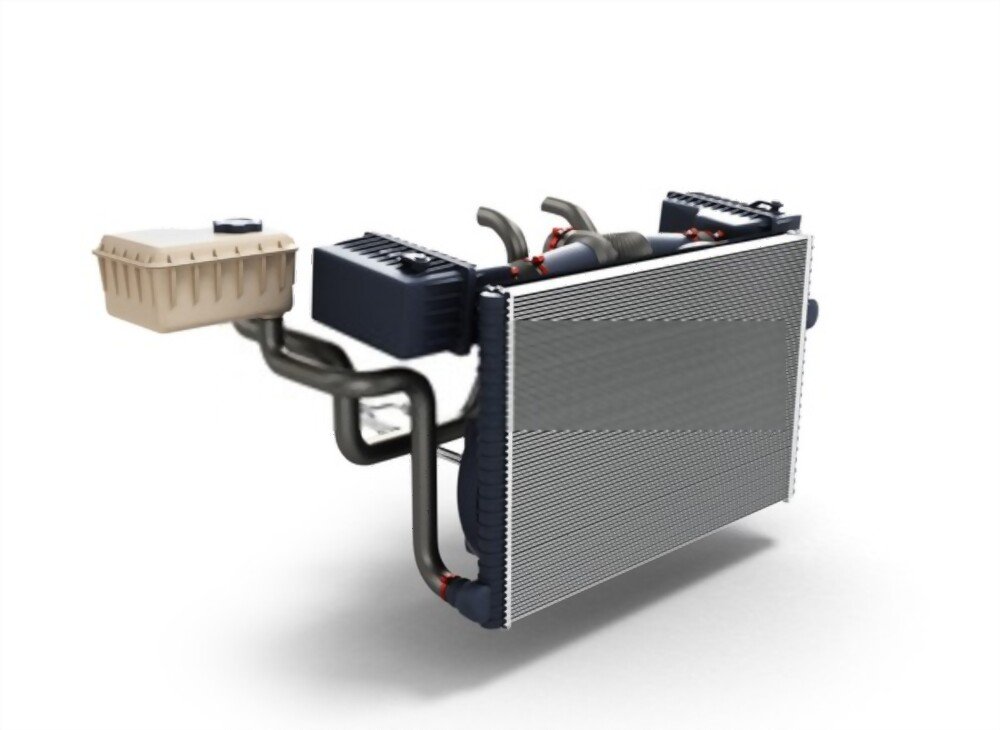

Transportation

In the automotive industry, PTC heaters are used to improve the heating within the vehicle including battery thermal management, seat heating, sensor de-icing, rearview, steering wheel heating, etc. This technology provides easy integration for in-flight applications, thereby making it an ideal choice to warm things like seats, walls, etc.

Healthcare

In the medical industry, safety is of utmost importance. These heaters offer under-body heating solutions and are ideal for human, veterinary, patient beds, blankets, and gurneys. These are also used in clinic chairs, dentist chairs, etc. The safety that comes with heaters makes them an effective material to be used in applications that involve direct contact with the skin. Moreover, you can also use them in fluid warming applications, shipment solutions, and drug storage.

Public Spaces & Stadiums

PTC heaters provide more energy efficiency, unlike alternative technologies that are available today. They operate seamlessly in extreme conditions and adapt to dynamic changes in temperature. Moreover, they are also suited for mass production and can be easily used in outdoor venues like amphitheaters, stadiums, park benches, etc.

Food, Beverages & Restaurants

PTC heaters are efficiently employed in an industry that is governed by FDA (Food & Drug Administration) regulations. From fluid to food warming in food storage shipment, the heaters are used in various stages of food processing. Also, in the restaurant industry, they are placed on countertops or plates for warming solutions or food delivery bags.

Final Thoughts

PTC heaters offer endless possibilities and can be easily remodeled in terms of sizes and shapes. The advantage of using the heater far exceeds the traditional heating system. Moreover, they are much safer and more efficient. Contact Narain Cooling to understand more about PTC heaters and get yourself one for your industry.