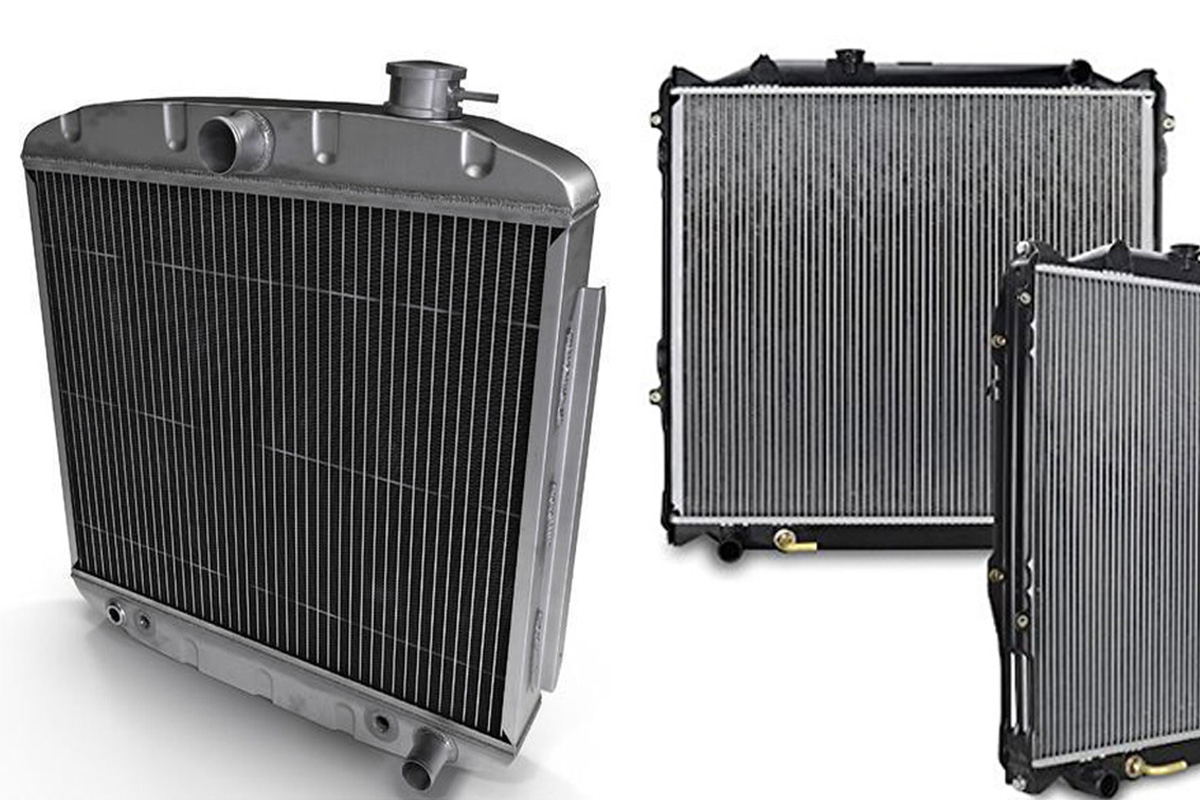

Condenser And Radiators are used for the purpose of heating & cooling, also act as heat exchangers that are used to transfer thermal energy from one medium to another Medium. The radiators are constructed to function in cars and electronics. A condenser and radiators is always a source of heat to its environment, this may be either for the purpose of heating the environment or for cooling the fluid supplied to it, as for automotive engine cooling. The condenser is designed for use in the summer cooling of automotive air conditioners. Air conditioners are the most common form of Condenser And Radiators. The condenser coils in an air-cooled conditioner remove heat from the inside air, expelling the heat to the outside, and blowing colder air into the house. the condenser is part of the air conditioning system & the radiator is part of the engine’s cooling system. Both condenser and radiator manufacturer in India has the same purpose i.e they Remove heat. The Ac condenser is Usually designed for summer car air conditioning, conditioning refrigerant flow in it.

Condenser And Radiators – A Simple Guide

It is the outdoor portion of an air conditioner or heat pump that either releases or collects heat, depending on the time of the year. Both split Condenser And Radiators are made of the same basic parts.

AC Condenser Types – How They Cool Your Home

There are various AC condenser types that are used in air conditioning systems. These are – air-cooled, evaporative, and water-cooled.

1. Air Cooled Condensers

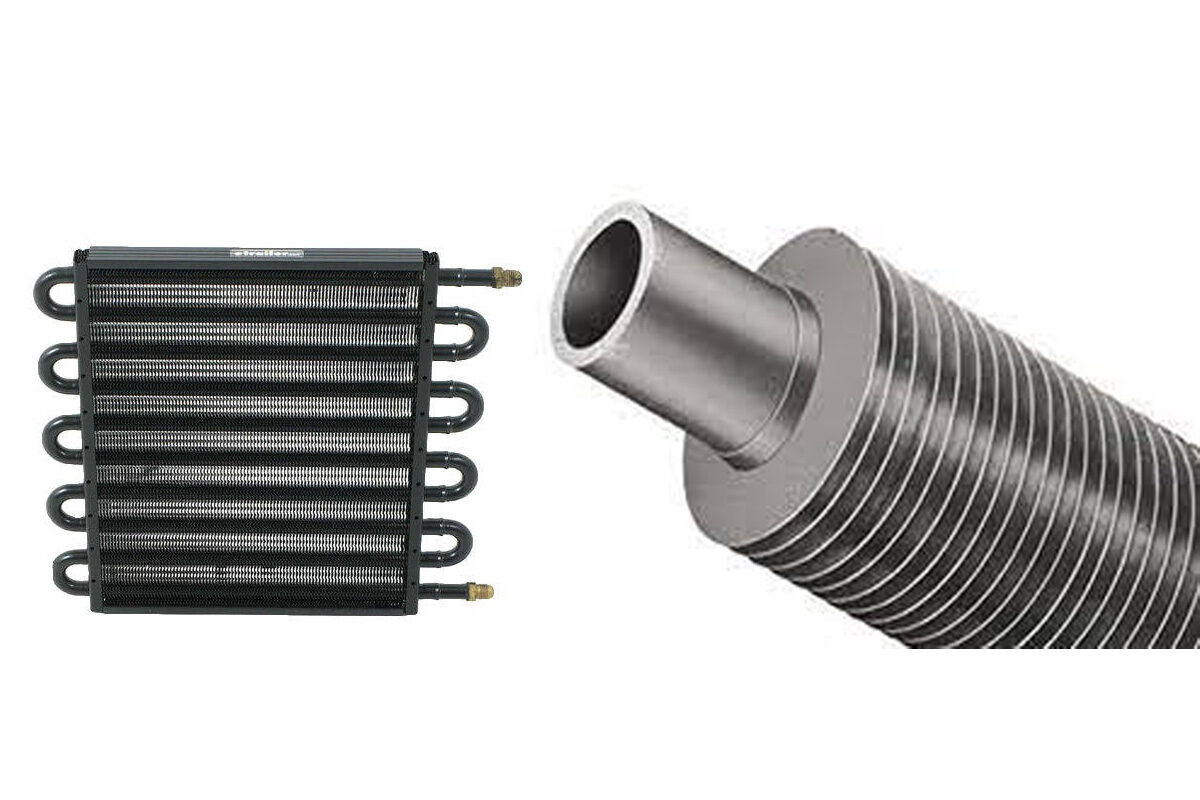

It is used in smaller area conditioning units. These condensers are also known as coil condensers because they are mainly made up of either aluminum or copper coil. It takes up more space than the water-cooled condenser. AC Condenser price in India is very affordable. There are 2 types of air-cooled condensers such as forced convection & natural convection. In forced convection, a motor-operated fan blows the air over the condenser coil. On the other hand, the air flows naturally in natural convection.

2. Evaporative Condensers

These condensers are a combination of both air-cooled & water-cooled condensers. The water is sprayed all over the coils. Simultaneously, the fan present there draws the air from the bottom of the condenser and then discharges it from the top side of the condenser. When the spray water comes in contact with the condenser, it gets evaporated quickly. Then it gets absorbed from the Condenser And Radiators.

3. Water Cooled Condenser

It is used in big packaged air-conditioners, large refrigerant plants, and central air-conditioning plants. Mostly used in places where a load of cooling is very high. No matter what type of water-cooled condenser it is, the water flows through one end of the piping for cooling the refrigerant and condensing it.

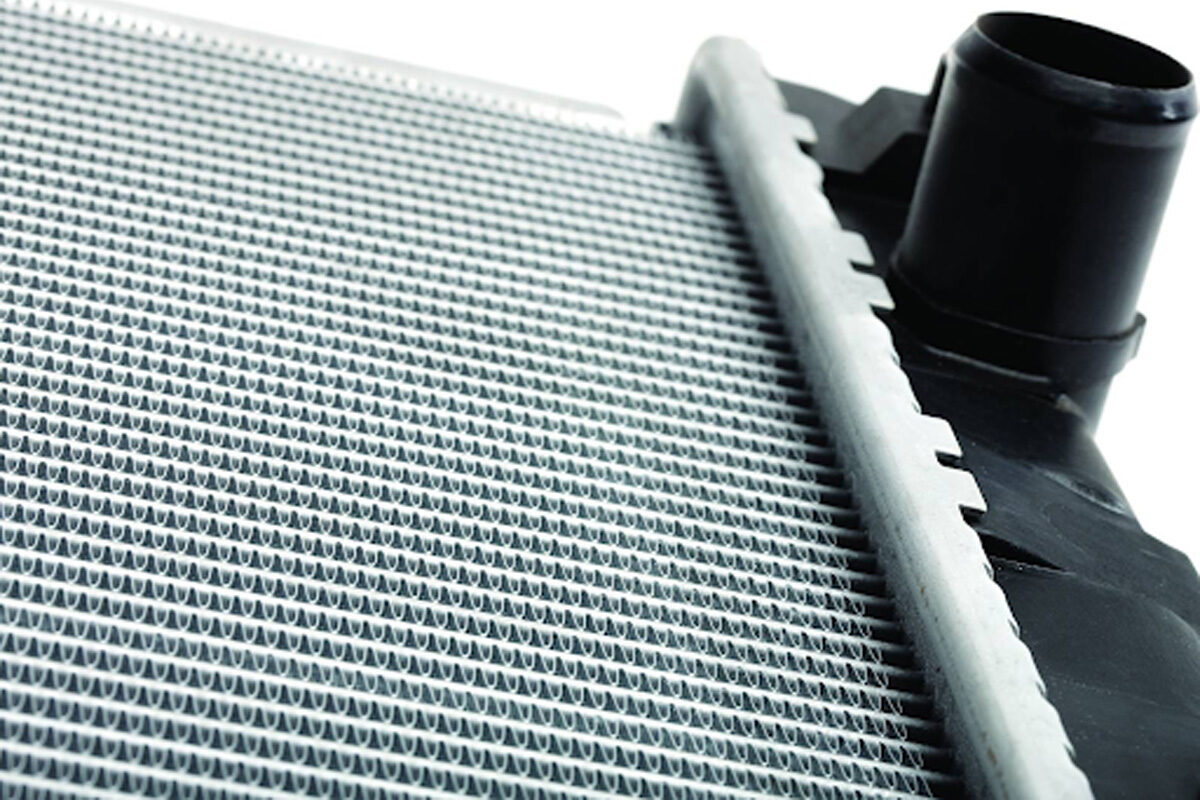

Microchannel Condenser

Microchannel condenser coils are all-aluminum coils with multiple flat tubes containing small channels (microchannels) through which refrigerant flows. Heat transfer is maximized by the insertion of angled and louvered fins between the flat tubes. The coils are designed to be lighter, more durable, provide better heat transfer, and require less refrigerant charge than conventional tube-and-fin coils.

Why is a condenser necessary?

Condensers are responsible for condensing the enriched vapors at the top, promoting the reflux of liquids to the column, and allowing the withdrawal of distillate. The Condenser plays an important role in this process by essentially dissipating the heat carried to the outdoor unit. This allows the cooling process to continue.

Micro Channel Heat Exchangers

Micro Channel Heat Exchangers are a variation of fin & tube heat exchangers. Usually water or refrigerant flows through tubes or enclosed channels while air flows cross-current through the connected fins. Micro Channel Heat Exchangers are based on patented innovations & designed to provide maximum thermal efficiency. Microchannel condenser coils demonstrate high efficiency and capacity.

Microchannel heat exchanging technology offers the following improvements over traditional fin/tube designs:

Higher performance & efficiency:

- Overall heat transfer performance is 20% to 40% greater

- Drastic reduction in airside pressure drops

Smaller weight & size:

- Coil face upon design conditions is 10% to 30% smaller

- A thin profile takes up less space

- Less weight Up to 60%

Reduced costs:

- Less refrigerant charge

- Reduced material cost

Proven reliability:

- Time-tested manufacturing processes & materials

- Higher corrosion resistance

- More robust construction

In conclusion,the role of condenser and radiator is very important in the process of heat transfer. They help to maintain the temperature of the coolant and prevent it from overheating. Moreover, they also protect the engine from damage caused by excessive heat. condenser and radiator