The massive requirement for a heating appliance in the industrial and various sectors meant less use of the traditional Ptc heater, which blows wire or tube for generating heat. This process takes a lot of electricity consumption and has high maintenance charges. But nowadays, the traditional heaters are replaced by Positive Temperature Coefficient (PTC) heaters.

They are built with modern technology and are highly reliable for use in various sectors as heating agents. It consumes less electricity and provides better output than the traditional heater, and more importantly is its uptime, where the coil of the traditional heater will melt after prolonged use. This Positive Temperature Coefficient (PTC) heaters can provide up to 30,000 hours of long life.

Benefits of Positive Temperature Coefficient (PTC) heaters

It can perform more effectively in small places and provide superior heat. It has several practical applications in various industrial and commercial uses too. We have researched a lot and put some of its applications. Here are they:

Anti-condensation agent

(PTC) heaters are super reliable and durable, and they have some fantastic properties, including dehumidification and anti-condensation properties. These properties will make the (PTC) heaters the best for food processing, food safety, and security of beverages in high-moisture places.

It provides continuous warm heat to the food and keeps them dehydrated, and this will not allow any food reaction to occur with moisture. Without the heating, food gets spoiled during the process, and manufacturers face massive losses.

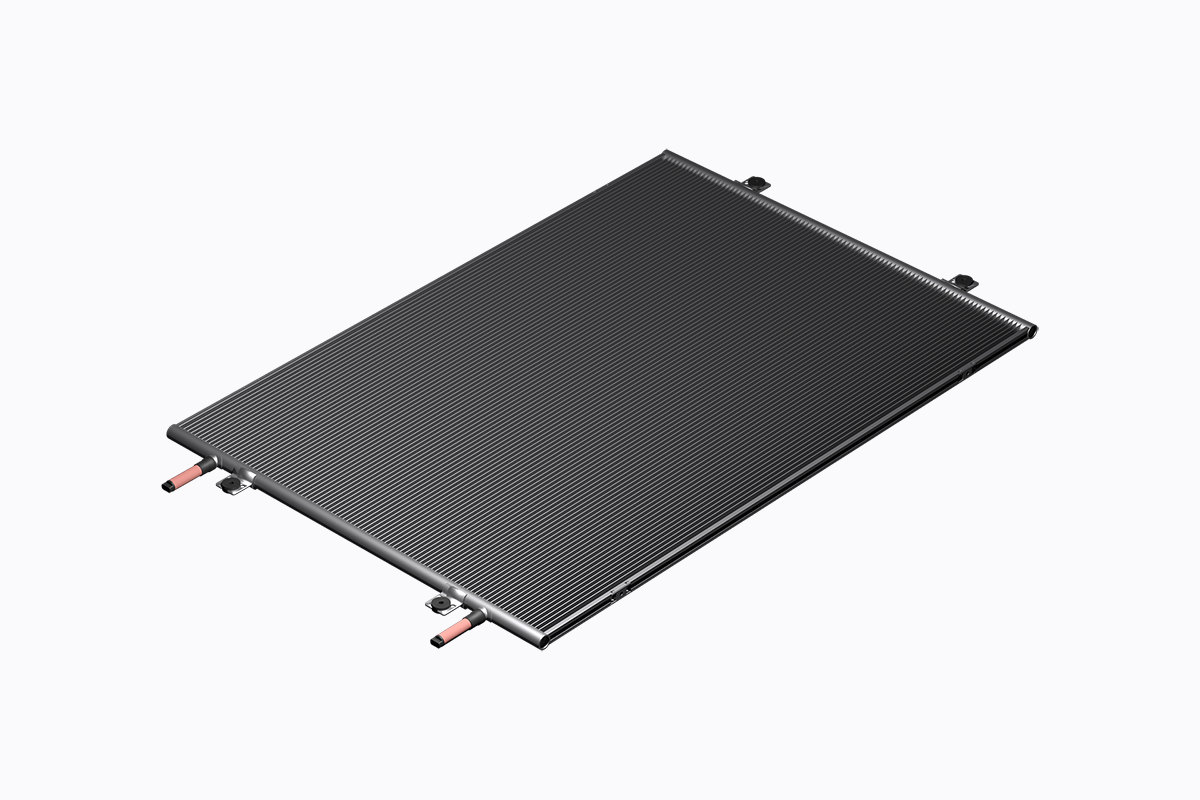

Automotive industry

Using the traditional automotive hearing methods is slow and steady. More importantly, they are much more expensive. Also, they will consume the oxygen and cooling of the area, which leads to suffocation and anxiety.

But now, the problem is resolved by using the Positive Temperature Coefficient (PTC) heaters. They are the best alternative for the solution and provide the most effective remedy. Now, all the automotive manufacturers are using these heaters and saving a lot of money and effects.

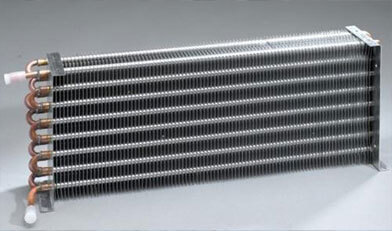

Heating food and beverages industries

One of the most common applications of (PTC) heaters is their use in the food and beverage industries. They are used for controlling the temperature of various food processing uses and heating a few places. It is used as a healing agent in hot coffee plates, temperature-controlled containers, food warmers, etc. They are consistent and can perform the heating non-stop for several hours.

What Is Unique About PTC Devices?

PTC heaters cannot overheat. These unique factors make the device self-limiting as its resistance increases, allowing the current through the device to decrease. They can also be considered self-controlling.

If the ambient temperature starts to decrease, the resistance of the heater will decrease, drawing more current and counteracting the cooling trend.

Positive Temperature Coefficient (PTC) heaters can be busy both from the file market or online platforms, and we recommend you buy them online. You will get proper documentation, authentic product, and more importantly, you are not supposed to go anywhere, and you get your order at your home.

For more info read also: PTC heater

Takeaway Points

There are many other applications of Positive Temperature Coefficient (PTC) heaters in cold regions. People used to install these heaters under beds which provide heat throughout the night, especially in army camps and shelters. These heaters are a revolution in the industrial sectors, and these applications will make them one of the most important things to install while setting up any industry.