Radiators – What are they?

A radiator manufacturer is a type of heat exchanger. It is designed to transfer heat from the hot coolant that flows through it to the air blown through it by the fan.

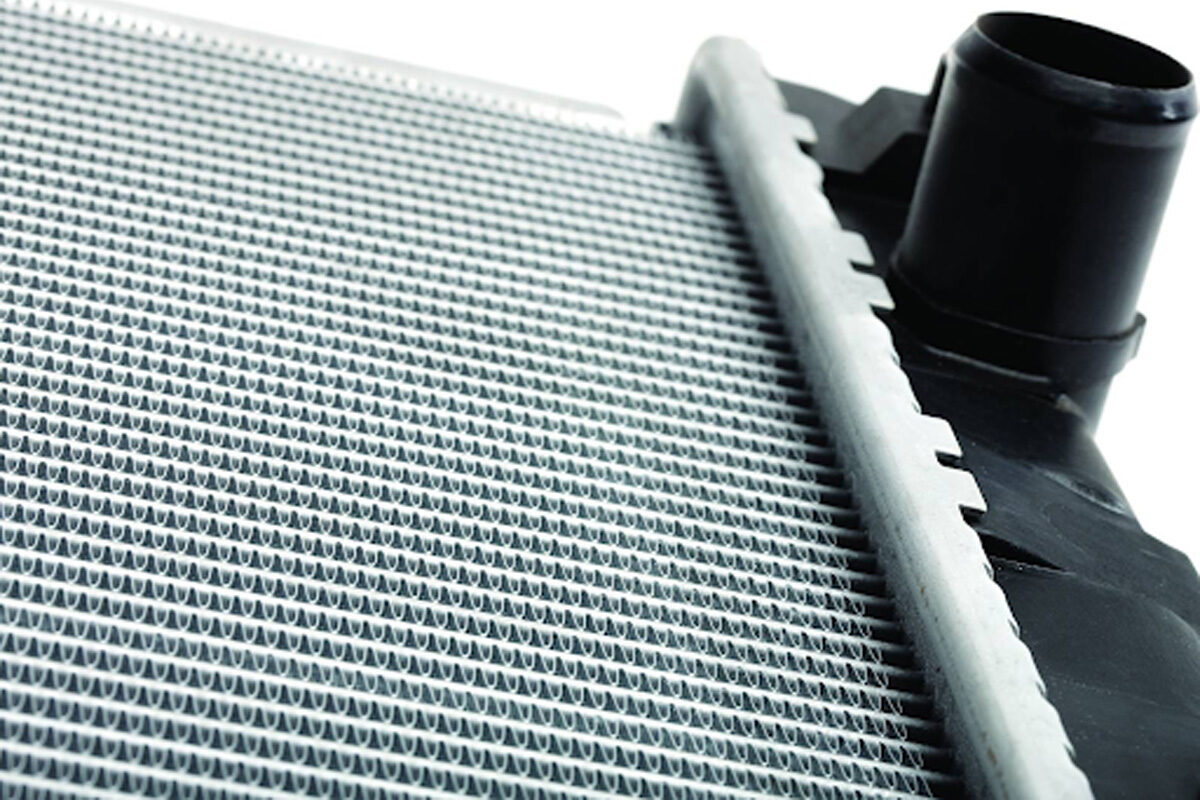

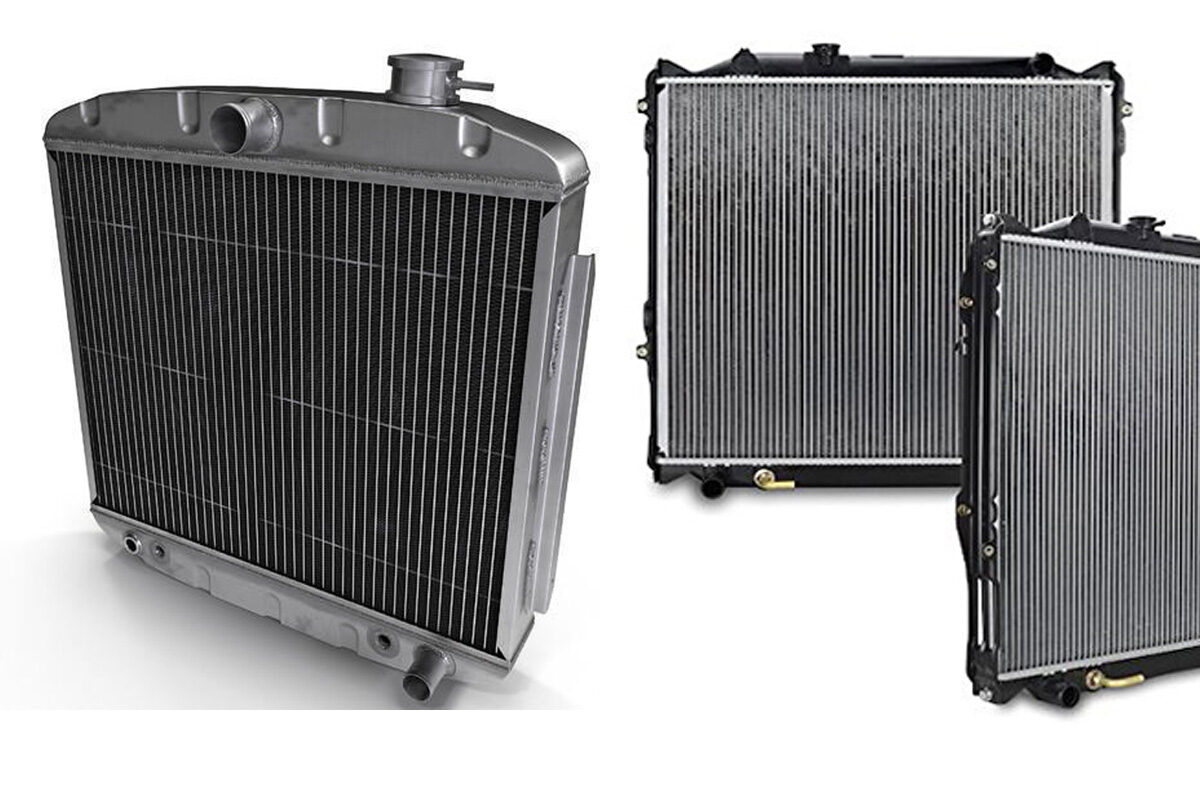

Most modern cars use aluminum radiators. These radiators are made by brazing thin aluminum fins to flattened aluminum tubes. The coolant flows from the inlet to the outlet through many tubes mounted in a parallel arrangement. The fins conduct the heat from the tubes and transfer it to the air flowing through the radiator.

The tubes sometimes have a type of fin inserted into them called a Turbulator, which increases the turbulence of the fluid flowing through the tubes. If the fluid flowed very smoothly through the tubes, only the fluid actually touching the tubes would be cooled directly. The amount of heat transferred to the tubes from the fluid running through them depends on the difference in temperature between the tube and the fluid touching it. So if the fluid that is in contact with the tube cools down quickly, less heat will be transferred. By creating turbulence inside the tube, all of the fluid mixes together, keeping the temperature of the fluid touching the tubes up so that more heat can be extracted, and all of the fluid inside the tube is used effectively.

Radiators usually have a tank on each side, and inside the tank is a transmission cooler. In the picture above, you can see the inlet and outlet where the oil from the transmission enters the cooler. The transmission cooler is like a radiator within a radiator, except instead of exchanging heat with the air, the oil exchanges heat with the coolant in the radiator.

The Best Radiator Manufacturer In India

Being the best in India, our vision is to become a global leading developer and manufacturer of OE, customized, and aftermarket, core, and complete radiators.

Our Mission is to add value to our customers, suppliers, and employees by providing superior products and services on time and at a competitive price, whilst practicing honesty and fairness throughout our corporation.

Having been in business for over 8 years, Narain Cooling Technologies has enjoyed a strong reputation in the Heat Transfer Industry.

What makes Narain Cooling THE BEST?

Narain Cooling Technologies’ aim is to continue to be at the pinnacle of our profession through innovation & is Radiator manufacturers in India and a new way of thinking by keeping with the rapid technical progress during the present period. We believe this has accumulated in the provision of quality products at a fair price as the markets dictate and expect.

The employees and management of Narain Cooling Technologies are dedicated to maintaining their position as the leader in the heat transfer industry. Narain Cooling Technologies promises to continue making these contributions while at the same time standing behind its products by delivering unparalleled reliability and service.

We extend our deepest gratitude to the supporters of Narain Cooling Technologies and ask for your continued love and encouragement.

We trust you will continue to place your confidence in Narain Cooling Technologies Pvt. Ltd.

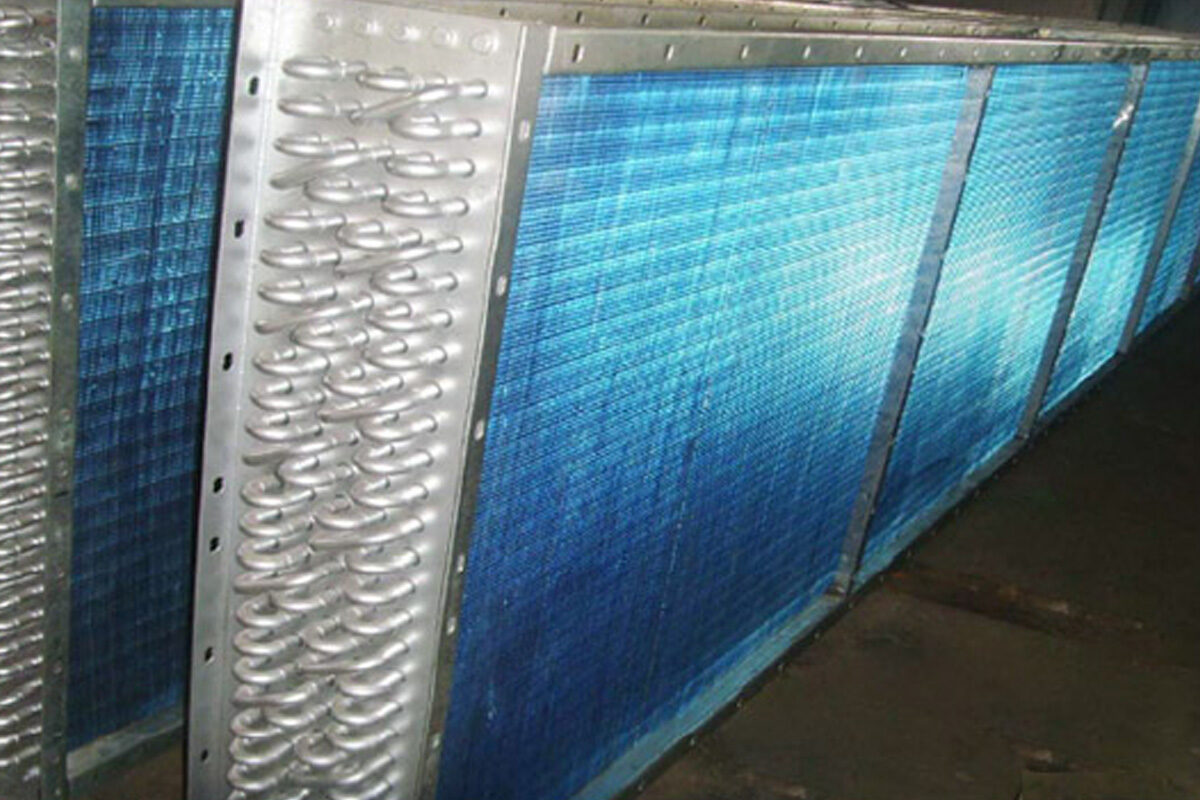

Narain Cooling Technologies (P) Ltd. is an ISO 9001:2015 and IATF 16949:2016 certified company for designing and manufacturing Aluminium Brazed heat exchangers for a wide range of applications and markets. Starting as a manufacturer of copper-brass radiators, Narain Radiator has now become a leading aluminium radiator manufacturers in India, an Aluminium brazed heat exchange solution provider.

Conclusion

Narain Cooling Technologies (P) Ltd. offers a wide range of best radiator manufacturer, end-to-end solutions to industries that make locomotives to radiology equipment and everything in between. We understand our customers’ needs first and then design coolers or cooling assemblies that seamlessly integrate with their systems and adapt to the final environment they are placed in.