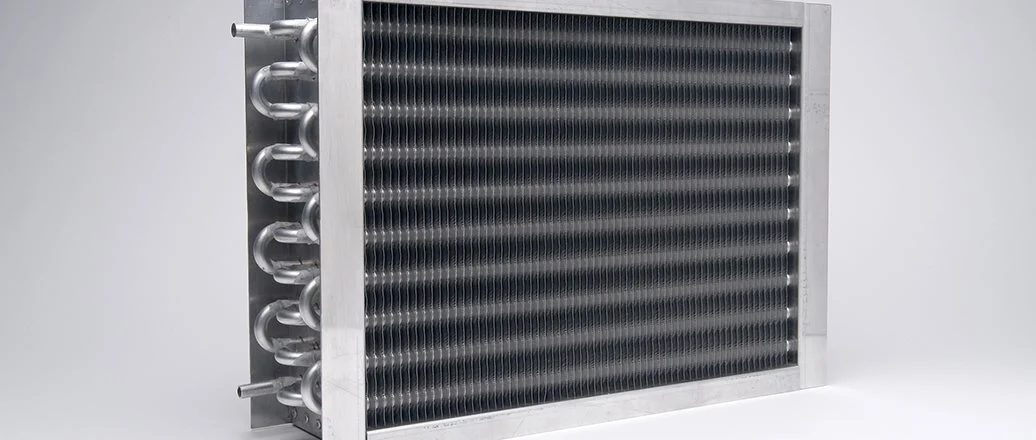

In this hot summer, we are sitting in a chilled room. Have you ever thought about how it is possible? That is because of heat exchangers. Heat exchanger applications are not only in domestic appliances but also in crucial industrial manufacturing sectors. They transfer heat between hot and cold streams to save energy. A heat exchanger with fins attached to the outer tube is known as a Finned Tube Heat Exchanger. In these heat exchangers, fins increase the surface area for heat transfer, which increases the rate of heat exchange.

What are Finned Tube Heat Exchangers?

Finned tube heat exchangers are the type of heat exchangers in which fins are attached to the outer tube of the exchanger. Adding fins facilitates the transfer of fluid outside the tube. It is for the transfer of air or another gas.

In a finned tube heat exchanger, an overall flow pattern is often crossflow, but it can also be counterflow or parallel flow.

A finned tube is very helpful as one of the fluids is air or any other gas in an air heat exchanger. There is a low air-side heat transfer coefficient, which increases the surface area of heat transfer.

Why Finned Tube Heat Exchangers are made of Aluminum?

- Aluminum is a lightweight metal than heavier metals like stainless steel or copper. In the case of radiators, the lightweight material improves the performance of the equipment.

- Aluminum is a great heat conductor, making it an excellent choice for radiators. While comparing to other materials, aluminum radiators heat efficiently and quickly reach the necessary temperature.

- It is a recyclable metal. So by buying aluminum radiators or fin tubes, you are getting an eco-friendly product.

Working Principle Of Finned Tube Heat Exchangers

In a finned tube heat exchanger, fins are outside the tubes. The liquid will flow through the finned tube with air or another gas flowing outside, increasing the heat transfer rate due to the greater heat transfer surface area.

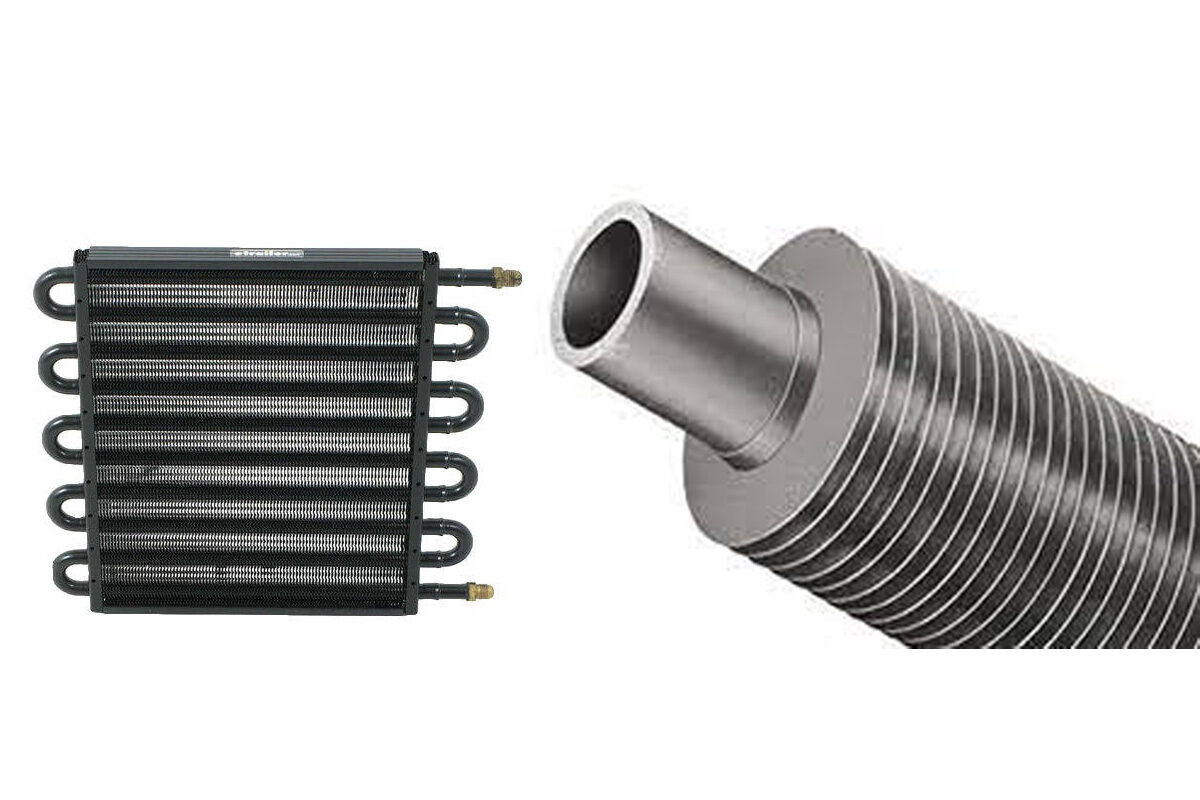

The fins on a crossflow tube exchanger are usually circular or square radial fins. Fins should be longitudinal rather than radial in a counterflow or can be parallel flow fin tube exchangers. In an enclosed heat exchanger, finned tubes work as internal tubes.

Uses Of Finned Tube Heat Exchanger

- Finned tube heat exchangers are helpful in the condition where the heat transfer coefficient inside the fluid is higher than the fluid outside the tube.

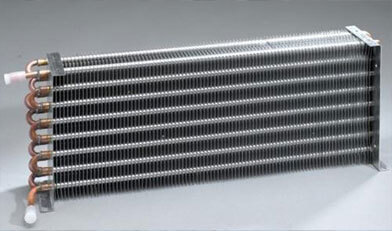

- Other finned tube air heat exchangers include automobile radiators. The truck radiator‘s job is to cool the hot water in the tubes by circulating air through them in a crossflow pattern. Also, the objective of the air conditioner evaporator coil is to condense the air traveling through it.

- Finned tube heat exchangers are helpful in the chemical industry, petrochemical industry, automobile (heavy truck radiators, car radiators) industry, etc.

- Recent developments have seen dry cooling for steam power plants grow rapidly. In this method, an air-cooled condenser replaces a water-cooled condenser.

- For different purposes, the shapes and sizes of fins are unique, like- S-shaped fins to increase the surface area for heat exchange in heavy truck radiators to increase the heat transfer rate. Therefore, these are the best truck radiators in use nowadays.

Post Related: Fin Tube Heat Exchanger: 6 Tips On How To Choose Your Most Suitable

Conclusion

One of the most emphatic discoveries in increasing tube heat transfer is the finned tube heat exchanger. The increased surface area allows a faster heat transfer between two components. Moreover, finned tube heat exchangers are advantageous for various industries like power, petrochemical, chemical, air conditioning, truck radiators( heavy truck radiators), and refrigeration.

At Narain Cooling Pvt. Ltd, we provide finned tubes made up of aluminum. Aluminum is the lightest and most recyclable metal. As a result, when you buy an aluminum radiator, you’re also getting an environmentally beneficial heat exchanger. They can pass on down the generations. You may obtain high-quality aluminum radiators made entirely of recycled material from Narain Cooling.