While buying an air conditioner people look for cooling capacity, and energy efficiency but nobody notices the condenser. So the condensers are equally important and help in long-term durability, cooling effectiveness, etc.

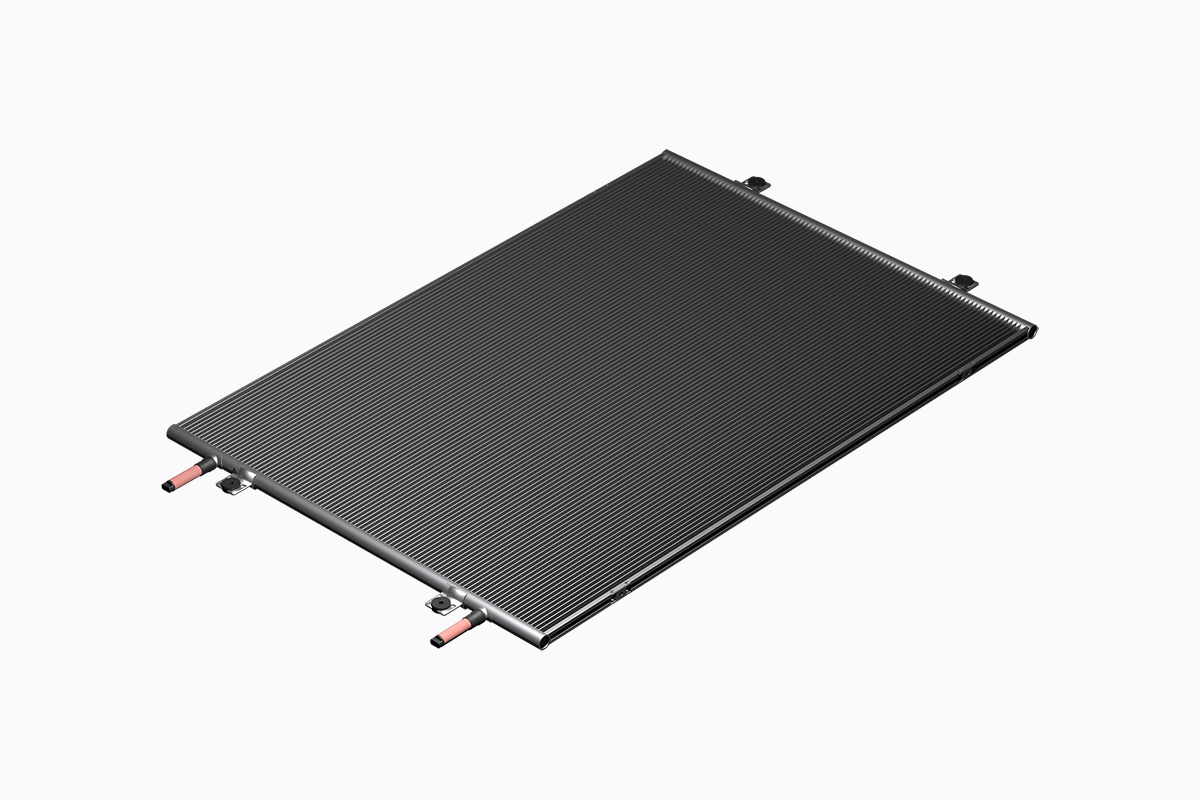

Microchannel condensers are best used in HVAC air conditioning systems.

It is the best option to target the needs of the HVAC industry. Furthermore, this helps to improve efficiency and cost also. In a Microchannel heat exchanger, only one fluid flows either water or refrigerant flows through the tube or enclosed channels while the air flows between the connected fins.

Types of Microchannel Condenser

- Air-cooled condensers

- Water cooled condenser

- Combined water and air-cooled condenser

These condensers are also called evaporative condensers and they are cooled by spraying water from above and then this cold air enters from the bottom and is blown across the coils.

The refrigerant inside the coil condenses as the water evaporating from the coil generates a cooling effect. The coil’s refrigerant gas is heated. Just by combining the water that was sprayed with the large column of moving air that was provided by the fan, it transformed into a liquid condition. Using a pump, the water that does not evaporate is cycled once more.

Uses

Many industries like transportation and chemical processing have been using micro-channel heat exchangers for decades. Additionally, due to its improved efficiency, it is widely used in the HVAC system. So due to its increased demand, the manufacturers are focusing on aluminum materials and brazing construction. As it is made up of single material there is a consistent heat transfer rate. It produces strong metallurgical alloy at the joints due to the high temperatures used in brazing. Thus, in this way, the resistance to heat transfer is reduced. We focus on limiting condensation, and corrosion thus improving the fluid flow.

Benefits of Microchannel Condensers

There are multiple technical benefits due to small hydraulic diameter channels. It is best to use a microchannel heat condenser in the HVAC industry due to its efficiency. It provides more surface area to refrigerants than larger tubes in the same space. It also requires less refrigerant. Due to its increased efficiency, it means smaller fans are used and thus lowering the overall energy of the system. On the other hand, there is less noise due to the small fans.

Comparison Between Copper And Aluminum Condensers

Aluminum condensers are light in weight as compared to copper condensers.

Condensers are always in contact with air so they are more resistant to corrosion. However, both are resistant to corrosion because an air conditioner’s cooling capacity is widely affected.

Why do we?

We have 8 years of experience and a good reputation in the heat transfer industry.

We are trustworthy and have built a strong reputation among all our clients. Our hardworking team members continuously contribute to the company’s development. You can always trust Narain cooling as a high-quality microchannel condenser manufacturer as we are ISO and IATF certified. Our professional experience helps us to remain at the top through our best ideas.

Conclusion

We are the best manufacturers of microchannel condensers and are always there to help clients in all possible ways.

We are the best manufacturers of Microchannel condensers and ensure reliable and durable products.

So these Microchannel condensers are beneficial for many businesses. Additionally, they save money and last long.

Microchannel condensers are becoming increasingly popular in a variety of industries due to their compact size, high heat transfer efficiency, and low pressure drop. These condensers can be used in a wide range of applications, including refrigeration, air conditioning, and power generation. Microchannel condensers are the future of cooling technology.

We are Air cooled condenser manufacturers, use the best manufacturing technology and raw material to ensure the reliability and durability of the product.