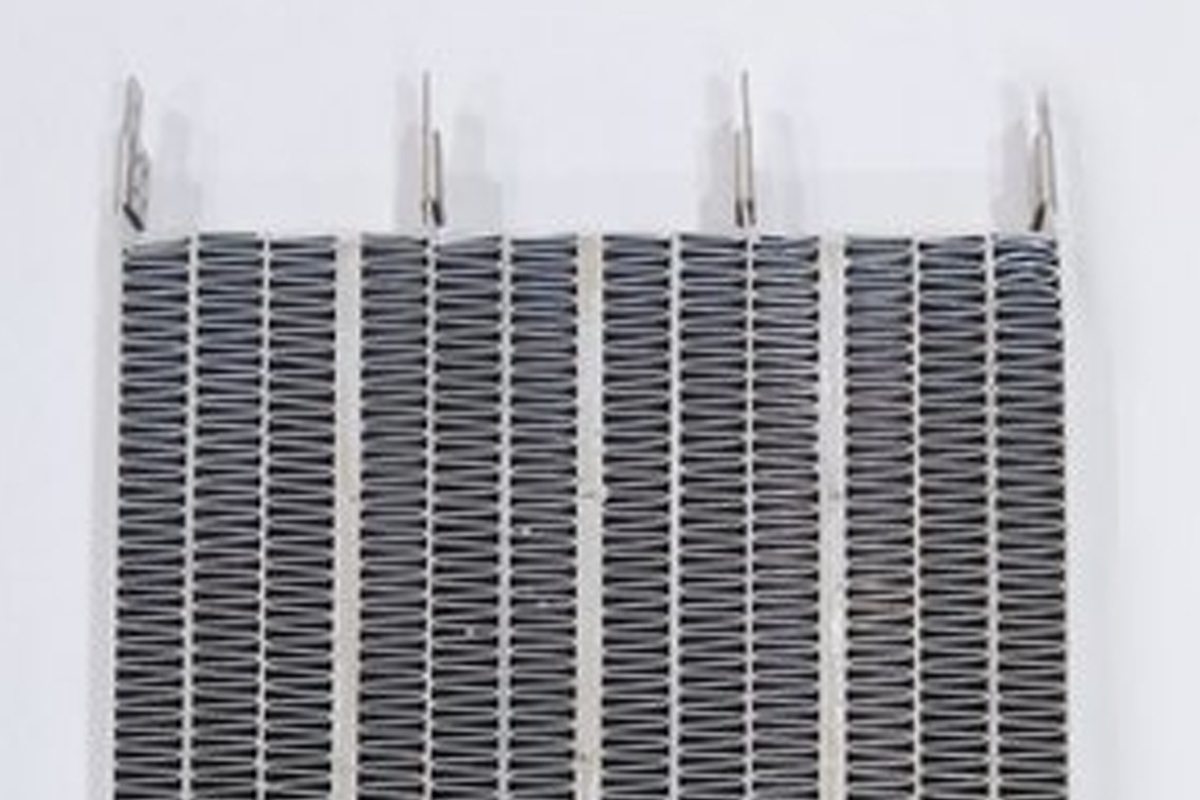

PTC heaters are made up of specialized heating discs with sophisticated ceramic materials with a positive temperature coefficient. These heaters are safe, powerful, and energy-efficient, allowing for excellent heat production and transfer even in the tiniest of areas.

Fin elements and honeycomb shapes are the two types of PTC heaters. While both types of heaters have several advantages over traditional heaters, users should be informed of the advantages and disadvantages of each before choosing one.

What is a PTC Heater, and how does it work?

Traditional resistance wires and coils are used to create heat in most ordinary heaters. This is not the case with a PTC heater.

Instead, it uses ceramic stones made of barium titanate as heating components. The PTC heater can operate as a sensor because of the material’s unique features. Without the use of additional diagnostic or feedback controls, the heater can operate in an open-loop mode. As a result, there is no risk of overheating with a PTC heater. It’s also much more efficient and trustworthy than the regular model, making it perfect for products that need to be heated safely, quickly, and uniformly.

What Can a PTC Heater Do for Your Next Project?

Now that we’ve learned a little more about PTC heaters let’s look at how they may help you with your next industrial project.

1. Improved Heating Functionality

We’ll start with one of the greatest benefits of PTC heaters. They enable users to generate the same amount of heat as a normal model while posing a fraction of the safety danger.

PTC heaters from Narain Cooling have a unique design that avoids all of the failure modes and hazards common with resistive wire, carbon fiber, and etched foil heaters. If a problem occurs, the system will “fail to cold” to make the effect unnoticeable. The heater component that failed will no longer take any extra current, while the rest of the heater will continue to operate normally.

2. Self-Limiting Characteristics

Because of its self-regulating properties, when the resistance of a PTC heater increases, the current within the device drops, the heater can sense the temperature around it and turn off if it rises above its specified setting.

This built-in safety and security function ensures that you’re not creating too much or too little heat for your project’s requirements.

3. Self-Regulating Characteristics

A PTC heater is also self-regulating and self-controlling.

A PTC heater modifies its usage in response to changes in the environment. When it reaches an ideal temperature, it can slow down production over time. The heater can keep its lowest output and maintain its temperature when it turns off.

4. Complex Heating Patterns

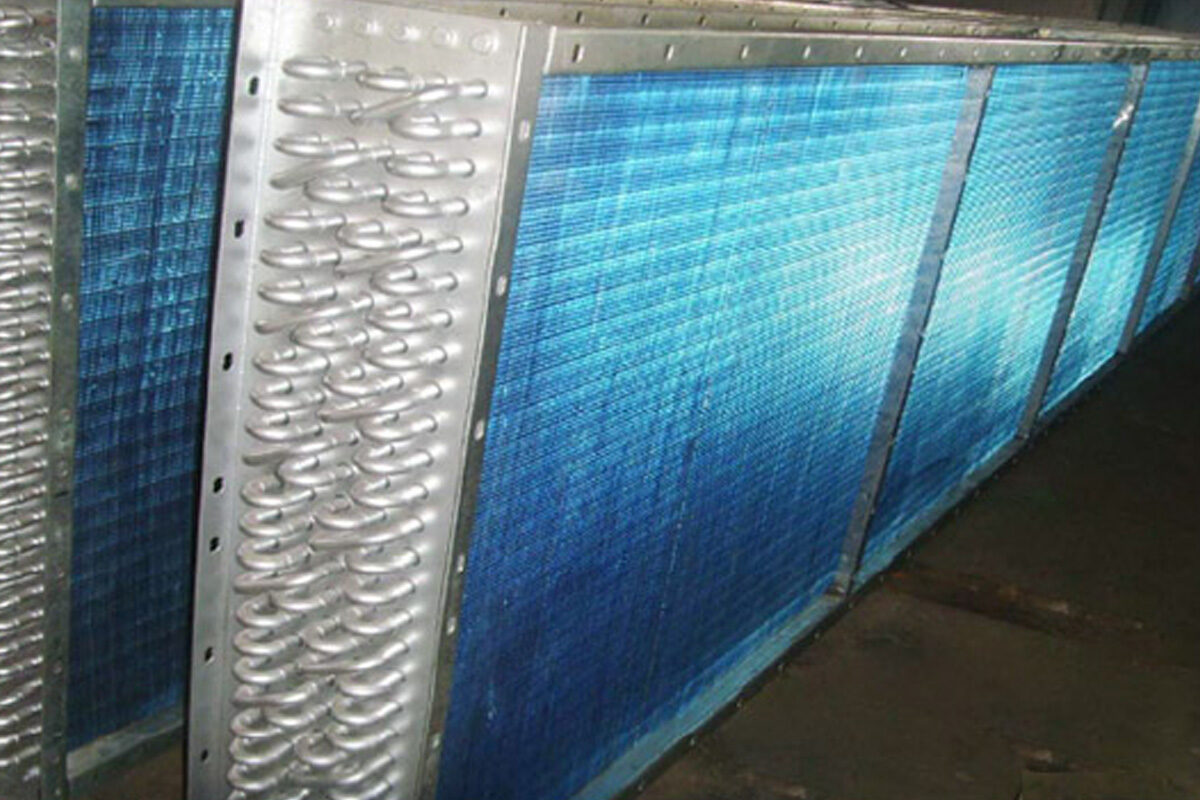

Narain Cooling Engineers can create a PTC heater to meet specific heating solutions as detailed as required, as indicated above.

You may set your temperature zones exactly where you want them to ensure maximum coverage while constructing your units. You can also alter the watt density and create custom holes and cuts as needed with simple tweaks.

This user control ensures that heat is distributed evenly and consistently. Every point on the surface of a PTC heater maintains its fixed temperature independently, eliminating hot and cold areas.

5. There are fewer components to deal with

A PTC heater has fewer working components than a traditional radiator. There will be less wear and tear to contend with, as well as fewer expensive components to replace. Additionally, your system’s ceramic components are less sensitive to water, chemical abrasion, and corrosion. These advantages boost your investment’s return and ensure that your control system lasts as long as feasible.

The few parts that make up a PTC heater only turn on when they’re needed, rather than maintaining high temperatures all the time. This feature contributes to the parts’ long-term durability and stability. It doesn’t take long for high temperatures to wear down materials when they are applied at a continuous rate.

6. Cost-Effective Compared to Traditional Models

PTC Heating is a smart and straightforward way to heat your home.

In the long term, this means less energy consumption, saving users a lot of money.

PTC heaters are designed to use full power at lower temperatures, allowing them to reach their threshold temperature as quickly as possible. They use less energy than typical heaters after they reach a constant state. When you pick PTC heaters, you can save money on a variety of things in addition to your utility bills. The lesser number of parts on a PTC heater, for example, helps to reduce maintenance and upkeep costs.

7. Materials that are compact and lightweight

Forget about those clumsy old heaters. When you buy a PTC heater from Narain Cooling, you get a small system and light. The footprint of the PTC unit should be as compact as possible.

Silicone heaters are less flexible than PTC heaters. You can even connect additional PTC heaters in parallel to meet the heating needs of a very wide area.

These materials aren’t very bulky, but they’re far from inconsequential. They’re the backbone of PTC heating technology, both innovative and efficient. Creating them, on the other hand, has no negative impact on the environment.

Here’s where you’ll find your next PTC heater

Are you ready to discover the ideal PTC heater for your industrial manufacturing environment now that you know a few of the top benefits they provide? If that’s the case, you’ve come to the correct place. Narain Cooling provides a wide selection of industrial PTC heating solutions, from fans and convection units to surface and air heaters, thermoelectric coolers, and innovative controllers. Please feel free to go over our online inventory and contact them if you have any queries.