What is a Microchannel Condenser?

In layman’s terms, a microchannel condenser is a device that cools the temperature down. It is an object that tries to the condenser, to convert the state of a gas or a vapour into liquid. Also, it releases a concealed form of heat that plays a role in the conversion of states without changing the temperature.

Where Is The Microchannel Condenser Coil Used?

These Condensers are used in various industries, objects and places – gas pipelines, boilers, air conditioners, chemical industries, steam power plants, chemical processes- distillation, Rankine cycle, etc.

Who Are The Manufacturers of Microchannel Condensers?

There are various manufacturers that produce condensers. Narain Cooling, one of the best manufacturers of condensers, produces them with a 100% guarantee of good quality.

Types of Microchannel Condensers Coils

There are three main types of Condensers that are categorized on the basis of an external object they use as an agent to carry forward the process.

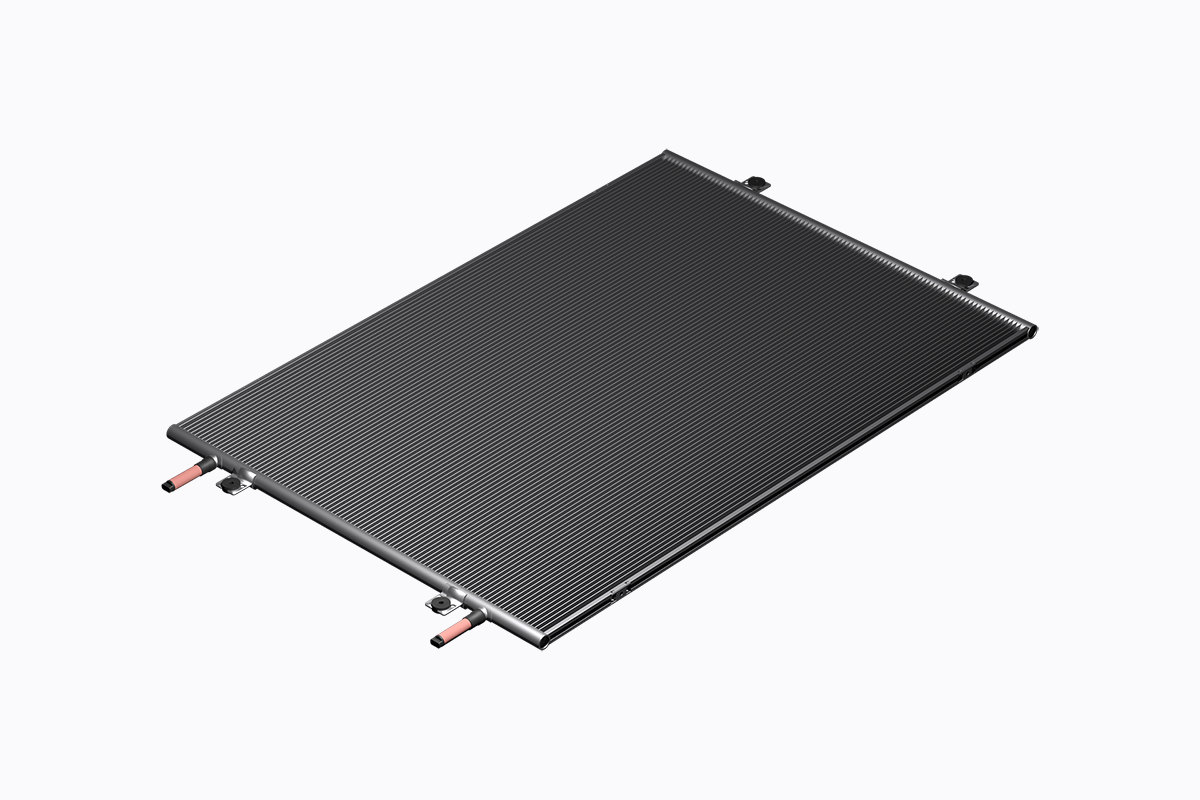

- Air-Cooled – As the name suggests, this type of condenser uses air to release the heat present inside the tube in the form of vapour or steam. A visual reference can help to understand this in a better way.

Further, the air-cooled condenser is sub-categorized into two kinds –

- Natural convection – Here, natural environmental air comes in contact with the coils present inside a machine and is used to produce cool air. This cool air replaces the warm air and hence continues the process of heat exchange.

They are made up of iron, steel and copper. The flow rate of the air is not that powerful because it is natural. Hence, it is used in the refrigeration systems that we use in our homes.

- Forced Convection – As the name suggests, this type of air condenser will use an external object for the inflow of air to go ahead with the process of heat exchange.

- Advantages of Air Cooled Condenser

- It has a low initial cost.

- It requires less flow area.

- It requires less cooling water.

- It has low maintenance charges

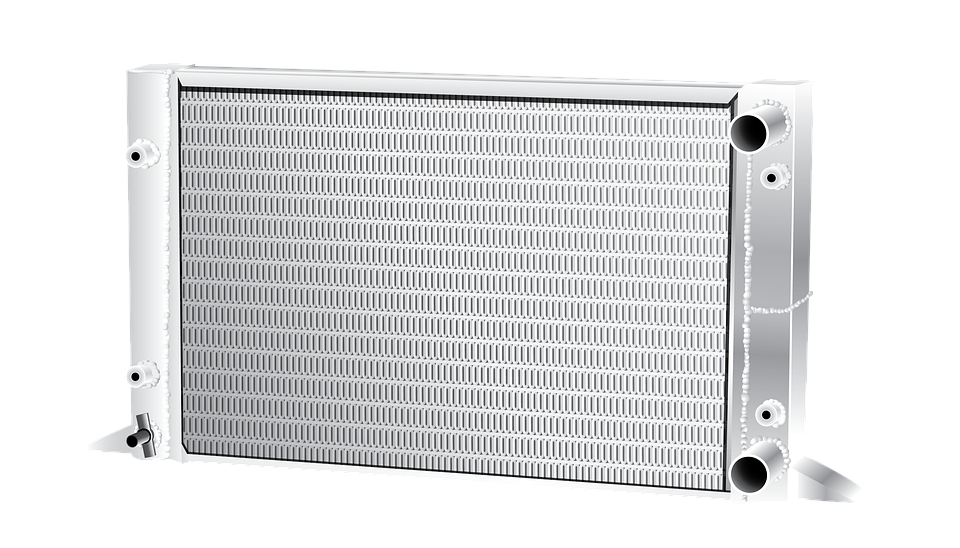

- Water-Cooled – As you can understand from its name, the water-cooled condenser uses water as an agent to release heat from the refrigerant. Water flowing through the tube exchanges the heat from the refrigerant vapour and then releases that heat through the outlet area.

They are used in the large refrigerating industries. Further, it has three sub-categories

- Double tube – A water tube is present inside the refrigerant tube.

- Shell and Coil Condenser – There is a coil of finned water tubing which is covered with a shell

- Shell and Tube Condenser – Here, the water tubes are present in a cylindrical shell, where the water is driven through the pipes and the refrigerant flows in the shell.

- Evaporative – It comprises a kind of pit through which the water is sprayed on the heated coil from above, and from the other side, the fan blows cool air from the bottom. Thus, both work simultaneously to discharge the hot air into the atmosphere.

It consumes less power as compared to the air-cooled and water-cooled condenser. It is mainly used in large cooling systems or where the external temperature is high.

Post Related: OverView Of Microchannel Condenser

Searching For a Trusted Microchannel Condenser Coils Manufacturer?

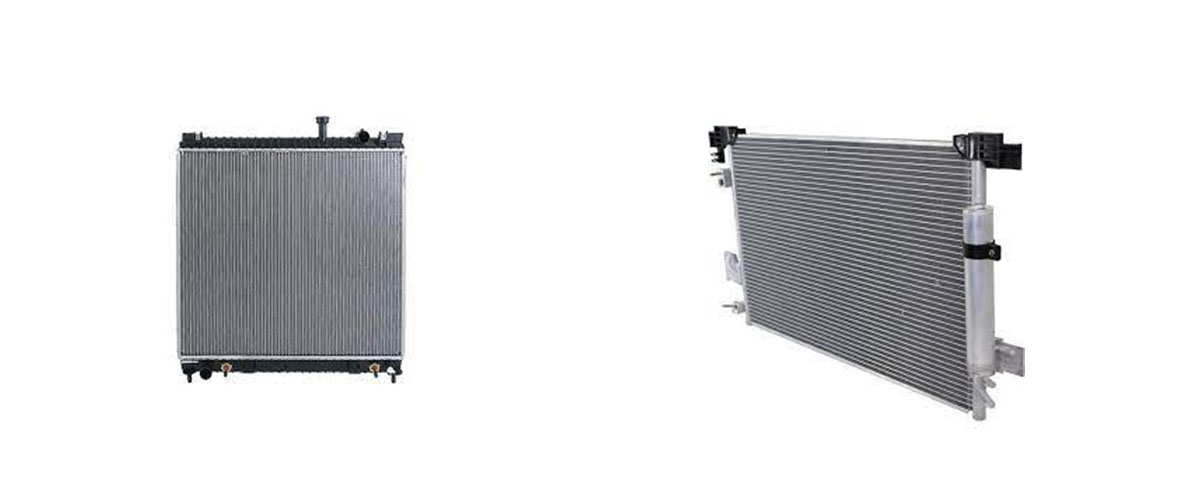

Your search is now over Narain cooling bringing you its Parallel Flow (PF) Air-cooled condensers (Micro Channel Condenser) and automotive condensers for heat ventilation and Air Conditioning (HVAC) applications.

We believe in providing the best quality product to our customers, Being in this profession for more than 8 years has given us experience and has taught us to deal with customers and resolve their issues.

As a Micro Channel Condenser Manufacturer, we use supreme manufacturing technology and raw materials to make our product powerful and durable. Trusting Narain Cooling will give you a stress-free life, with no mess of product damage, and timely services.